أحدثت أدوات الماس نقلة نوعية في قطاعي تحضير وتصنيع الأسطح، إذ وفرت دقة وكفاءة لا مثيل لهما مقارنةً بالأدوات التقليدية. يتمثل الاختلاف الرئيسي في مادة الكاشطة المستخدمة؛ فالماس، كونه المادة الأكثر صلابة، يوفر قدرات قطع وطحن وتلميع استثنائية. في المقابل، تستخدم الأدوات التقليدية عادةً مواد مثل كربيد السيليكون أو أكسيد الألومنيوم، التي تتآكل بسرعة أكبر وتُنتج حرارة أكبر أثناء التشغيل.

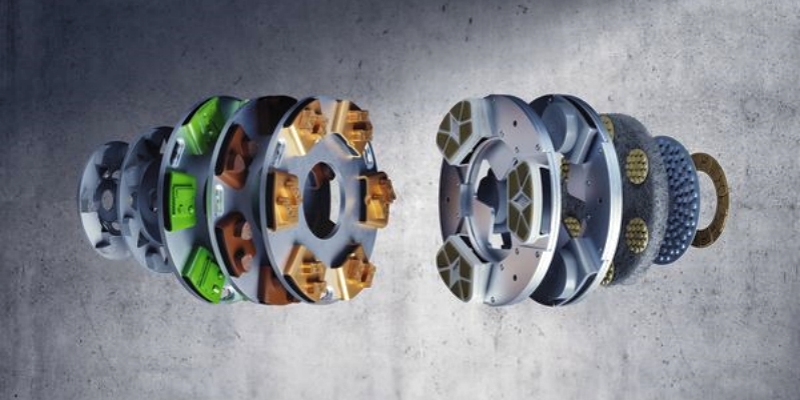

من العوامل المهمة الأخرى متانة أدوات الماس وأدائها الثابت. فهي تحتفظ بشكلها وحدتها مع الاستخدام المطول، وهو أمر بالغ الأهمية للمهام الصعبة، مثل طحن الخرسانة أو تلميع الأحجار. على سبيل المثال، أدوات شوامبورن نوك أون الماسية صُممت هذه الأدوات لتضمن المتانة وسرعة التغيير، مما يجعلها مثالية للمقاولين المحترفين الذين يبحثون عن نتائج موثوقة. إلا أن الأدوات التقليدية تتدهور بسرعة، مما يؤدي إلى تشطيبات غير متساوية وارتفاع تكاليف الاستبدال.

تتميز أدوات الماس أيضًا بالدقة والمرونة. فهي قادرة على التعامل مع الأسطح الصلبة كالجرانيت والمواد اللينة كالرخام دون المساس بالأداء. تُعد هذه القدرة على التكيف أساسية للمهام المتخصصة، مثل تحديد الحواف أو التلميع الدقيق، حيث وسادات مرنة لسطح العمل توفر مرونة وتحكمًا ممتازين للزوايا الضيقة والأسطح المنحنية - وهي المناطق التي غالبًا ما تفشل فيها الأدوات التقليدية.

من حيث الكفاءة، تتفوق أدوات الماس بشكل ملحوظ على نظيراتها التقليدية. فهي تقطع أو تطحن أسرع، مما يقلل وقت العمل وتكرار تغيير الأدوات. على سبيل المثال، أدوات طحن المعادن XPS صُممت هذه الماكينات لتحسين سرعة الطحن مع تقليل التآكل، مما يُمكّن المستخدمين من تغطية مساحات أكبر بفعالية أكبر ونتائج ثابتة. هذه الكفاءة المُحسّنة تُؤدي إلى توفير كبير في الوقت والتكلفة في المشاريع الكبيرة.

وأخيرًا، تُسهم أدوات الماس في بيئة عمل أنظف، وتُقلل من تأثيرها البيئي. دقتها تُقلل من الغبار وتُضفي تشطيبات أكثر نعومة، مما يُقلل الحاجة إلى صنفرة أو تنظيف إضافي. وهذا يُفيد بشكل خاص في الحالات التي تكون فيها النظافة أساسية، مثل أعمال التجديد الداخلية أو مشاريع البنية التحتية العامة.

بفضل تركيبتها المادية المتميزة، وعمرها الافتراضي الطويل، وأدائها المُحسّن، تُعدّ أدوات الماس الخيار الأمثل للمتخصصين في قطاعي البناء والتصنيع. وبينما قد تظل الأدوات التقليدية مناسبة للمهام الخفيفة أو التي تتطلب ميزانية محدودة، فإن فوائدها وقدراتها طويلة الأمد تدفع هذه الصناعة إلى الأمام.